Water Electrolysis for Hydrogen Production

Ensuring Process Safety and Product Quality Using Oxygen, Hydrogen, and Moisture Analyzers

Developments in recent years to reduce greenhouse gases have prompted many countries to achieve a net-zero target by 2050. To achieve these goals, these countries seek to maximize energy sources that minimize emissions. Hydrogen as a fuel offers one such path..

Hydrogen, a versatile energy carrier, doesn’t produce carbon emissions, such as CO and CO2, when burned. Also, when it’s produced in a climate-friendly manner, hydrogen significantly contributes to reducing CO2 emissions in industry and transportation. As such, it will play a vital role in the success of the global energy transition.

One process that will make a major contribution to this effort is hydrogen production via water electrolysis, using renewable energy to power the process. The hydrogen produced in this way is called “green hydrogen.”

Water electrolysis

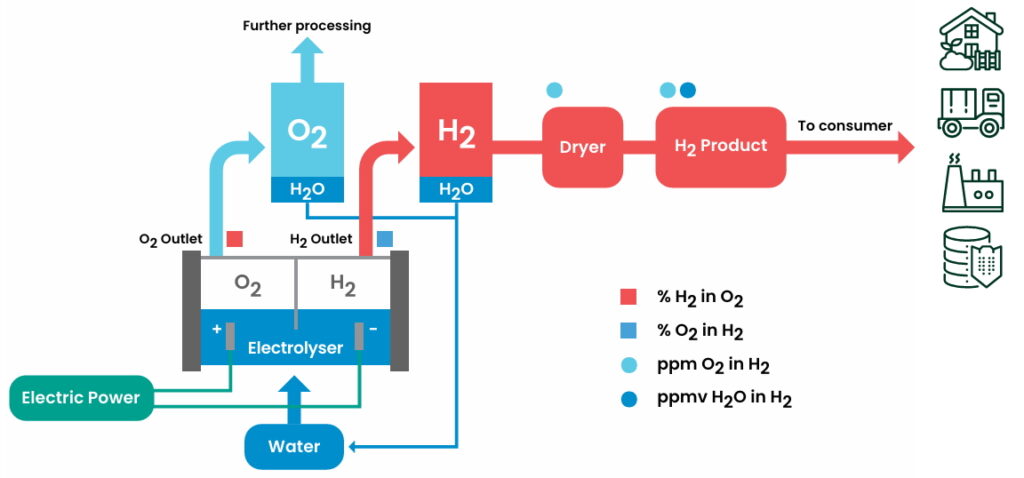

An electroyzer passes an electrical current to split water molecules into hydrogen and oxygen. The cell, the core of the electrolyzer where this process takes place, features two electrodes. The electrodes are immersed in an electrolyte separated by a membrane. Water splits into oxygen and hydrogen at the electrodes, while the membrane separates these produced gasses.

The membrane keeps these two gases separate during the splitting process, moving the oxygen to its own outlet. Crossovers of these gases on the membrane may occur, however.

PANAMETRICS understands the demands of this process and offers solutions for all the necessary analytical measurements for water electrolysis in its portfolio.

Hydrogen measurement

Hydrogen is highly flammable and can react explosively with oxygen. It is important to know if the oxygen content approaches the lower explosive limit in the hydrogen stream, due to any leaks or membrane cross-over. It is also critical to continuously monitor for leaks on the oxygen and hydrogen side of the electrolysis cell, so that this does not approach the explosive limit of the gas mixture. This safety relevant measurement indicates the health of the overall process and efficiency of the membrane. It always should be done with reliable, robust and proven technology.

Reliable and accurate analysis of hydrogen concentration in a compact, robust package.

The Panametrics XMTCpro Thermal Conductivity Binary Gas Analyzer reliably monitors hydrogen in oxygen and oxygen in hydrogen. Typical measurement ranges are 0 to 5% to signal a membrane malfunction. Safety Integrity Level certified, the analyzer is explosion-proof, flame-proof, weather-proof and insensitive to vibrations. With a built-in display, the XMTCpro is also compact, ideal for tight spaces and Modbus enabled, streamlining the monitoring process and allowing advanced connectivity across customers’ networks. The XMTCpro is designed for durability, requires little calibration and enables the customer to reduce the total cost of ownership of the gas analyzer

Benefits

• Proven technology in a a simple, easy-to-use, compact design reduces system solution costs

• Rugged constructionand no moving parts means extremely stable output with real-time error detection

• Doesn’t require frequent field calibration

• Basically maintenance free by design

• Stands up to harsh environments, withstanding shock and vibration

Key features

• Weather- and explosion-proof versions

• Extremely stable measurement thermistors

• Button-activated calibration

• PC interfaces for digital output

• Standard and custom calibration ranges between 0% and 100%

• High level of reliability with SIL 2 by design

O2 Analysis

The hydrogen produced during electrolysis typically contains high levels of moisture and varying amounts of oxygen. This moisture and oxygen are removed to produce high purity hydrogen. This is necessary to meet gas quality specifications for compressed hydrogen in applications such as fueling stations.

Reliable oxygen measurement in a compact, unique design.

Panametrics oxy.IQ galvanic cell transmitter detects the lowest possible oxygen impurities in the hydrogen stream, delivering 17 different percentage and ppm measuring ranges. It delivers reliable measurement in a compact design.

Benefits

• Proven galvanic fuel cell sensor technology provides superior performance, accuracy, stability and long life

• Compact analyzer design provides easy installation and system solution flexibility

• Innovative design eliminates the potential for negative signal output, reduces sources of contamination

• Built-in microprocessor with intuitive user interface to easily select range, trim outputs and perform calibration

• User-selectable ranges, calibration, sensor diagnostics with keypad simplifies programming

• Background gas insensitivity and acid gas sensor options ensure accurate measurement and analysis

Key features

• Display with keypad, user interface with diagnosis function

• Sensor-failure and lifetime monitoring features

• User-programmable, low maintenance, economical, compact

• Wide range of different calibrations covering ppm and % O2 ranges

Trace moisture measurement

In most electrolyzer applications, the exit gases are saturated with water. Since water vapor doesn’t burn or carry energy, dehydration is necessary to effectively transport, store and use the hydrogen produced during electrolysis.

Panametrics HygroPro II / HygroPro XP

Intrinsically safe or EExd, moisture transmitter general purpose and hazardous area use.

Panametrics was founded in 1960 with the introduction of the patented thin-film, aluminum oxide moisture sensor. Today, we use this technology in the intrinsically safe and highly versatile HygroProII and EExd rated HygroPro XP transmitter. The HygroProII / XP combines moisture measurement with built in temperature and pressure sensors to meet the demands of rugged industrial applications, including hydrogen production

Benefits

- Compact transmitter with moisture, temperature, and pressure sensors mounted on a single probe allows installation where space is at a premium.

- Measurements at pressures up to 345 bar

- Large dynamic dew/frost point measurement range (-110 °C to +60 °C)

- Sensors are easy to replace in the field

Key features

- Versions for use in Hazardous area

- Ambient to ppb moisture levels using aluminium oxide moisture sensor

- Built-in temperature and pressure sensors

- Integrated display/user interface

- HART communication over the 4 – 20 mA analog output

The DewPro Moisture Transmitter is an ideal, low-cost, explosion-proof moisture transmitter for the dryer application in water electrolysis.

Benefits

• Provides long calibration stability and quick response times

• MMY30’s integral flow cell for filtration and flow regulation is ideal for moisture monitoring in various process environments

Key features

• Loop powered, 4-20mA transmitter

• Integral filtering and flow regulation

• Hazardous area configurations available

Turnkey complex measurement solutions.

Panametrics pro.IQ and O2.IQ are complete plug-and-play systems that reliably ensure moisture and oxygen measurement. Simply install the transmitter, connect the power supply, and gas inlet – the analyzers are immediately ready for use.

INTECH CONTROL, in cooperation with PANAMETRICS, will be pleased to design and implement an analytical system tailored specifically to your application, in which multiple devices can be integrated into a single compact solution.

Copyright Notice

The article “Electrolysis of Water for Hydrogen Production” is the intellectual property of INTECH CONTROL spol. s r.o. and is protected under applicable copyright laws.

Any reproduction, distribution, publication, or other use of this article, in whole or in part, in any form, is not permitted without the prior written consent of INTECH CONTROL.